Wednesday, 31 July 2013

Tuesday, 30 July 2013

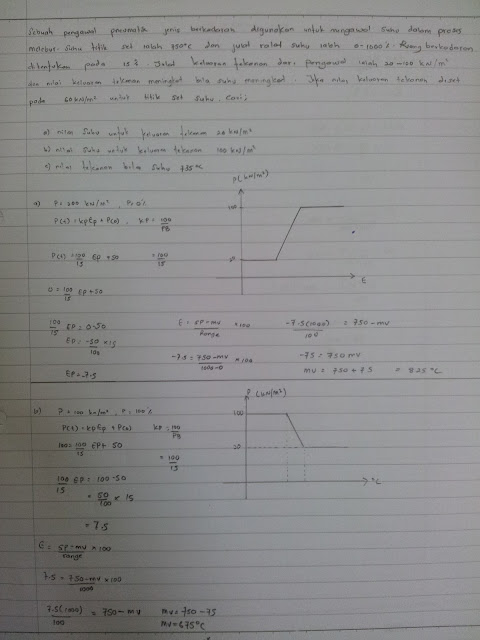

formula for chapter 2

- CONTROLLER OUTPUT IN PERCENT.

Controller output % = current output - minimum output X 100

maximum output - minimum output

- MEASURE VALUE AS PERCENTAGE

Measure value in % = MV - minimum MV X 100

max MV - minimum MV

- SET POINT AS PERCENTAGE VALUE

Set point % = SP - min value X 100

max value - min value

- ERROR AS PERCENTAGE VALUE

Error point % = % SP X MV X 100

max value - min value

- PROPORTIONAL BAND

Proportional band , PB = 100

proportional gain , KP

PB = 100

KP

- CONTROLLER OUTPUT

P = Kp*Ep X P(0)

- POSITIVE ERROR BAND

Positive error band = max permissible positive error X100

temp range

- NEGATIVE ERROR BAND

Negative error band = max permissible negative error X100

temp range

- PROPORTIONAL CONTROLLER

E = SP - MV

P(i) = KP*EP + P(0)

Tuesday, 23 July 2013

CHAPTER 2

PRINCIPLES

OF CONTROLLERS

2.0 EXPLANATION

OF PRINCIPLES OF BASIC CONTROLLERS

The main component of controller are :

a) Comparator

mechanism

b) Controller

c) Feedback

mechanism

Controller is a

device which receives input from two points :

(i)

a value which is sent by transmitter

(ii)

a value which is set by set point

The output from

the controller is send to the valve controller.

Figure

2.0 : Block Diagram of controller

Figure

2.0 shows the input controller is a signal which is sent by transmitter. This

signal is known as a transmitter signal (MV) and set point. If the output

depends on the two inputs functions well and the process is in a stable

condition, then the transmitter signal is similar to the set point. The comparator mechanism functions as comparator

of both input signals. An error will exist if the input value is not the same.

The detector will detect the error signal and determine if there is imbalance

between error signal and feedback signals. If there is a difference, the

detector will balance both of these signals. The feedback mechanism is a

mechanism which balances the system. The feedback signal is always similar to

the output signal.

The main components of controller

are :

(i)

Comparator mechanism. It consists of two bellows which is

for transmitter signal and set point signal. Its function is to differentiate

both the input signals.

(ii)

The controller consists of a flapper and nozzle. Its

function is to detect the error signal from the different output and the

feedback signal.

(iii)

The feedback mechanism consists of the feedback bellows. Its

function is to balances and stable the system. It also has an effect towards

multiple output of a controller.

2.1 EXPLANATION

OF BASIC CONTROLLERS COMPONENTS

2.1.1

Bellows

The structure of a bellow is shown in Figure 2.1. It consists of a thin metal which is formed into a wave cylinder shape. Air pressure will depress a bellow. When air pressure is increased, bellow will extend and displacement exists. This displacement is linked to the convenient‘lever’ for give the pressure increase reading. This displacement force include in mechanical force categories.

2.1.2 Flapper Nozzle

Flapper nozzle is a displacement

transducer which the displacement into a differential pressure parameter.

Figure 2.2 shows a structure of flapper nozzle. Basically air is used as work

liquid. Air will give a constant time about 0.1s. Flapper nozzle is used for

measuring of displacement between load cell. This displacement is very small.

Figure 2.2 :

Flapper Nozzle

2.1.3 Restrictor

Accuracy of an

instrument is guaranteed by manufacturers only for a certain limit. Normally it

is stated in the form of a full scale percent of that particular instrument.

Deflection from the specification is called restrictor error.

2.2 DESIGN OF

SCHEMATIC CIRCUIT FOR CONTROLLER ACTION TYPES

There

are three types of controller :

a) Proportional

controller

b) Integral

controller

c) Derivative

controller

2.2.1 Types of Controller

There are a few types of controller

used to control a process either in a form of Proportional output to the error,

Proportional and Integral to the error or Proportional and Derivative output to

the first error.

Controller can be used in the form

of single mode of Proportional, Integral, or Derivative, two mode of

Proportional and Integral (P+I) and Proportional and Derivative (P+D), and

three mode of Proportional, Integral and Derivative (P+I+D).

The

figures below show the design of schematic circuit for controller action types.

(i) Proportional Controller (P)

(iii)

Integral Controller

(iv)

Derivative Controller (D)

(v)

Proportional + Integral + Derivative Controller (P+I+D)

Subscribe to:

Comments (Atom)